Seal Gas Heaters

Seal Gas Heaters

Seal Gas Heaters

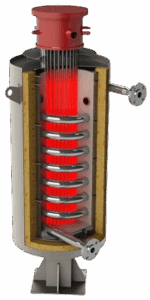

To enhance gas sealing systems with Fati’s high-performance Seal Gas Heaters, designed for reliability and long-term efficiency. Our robust construction ensures superior heat transfer, corrosion resistance, and extended service life even in demanding industrial environments. Our heaters are expertly designed for heating a wide range of process fluids, especially in high pressure applications. Each heater is custom engineered by our technical team to meet specific client requirements and technical specifications. Ideal for refineries, petrochemical plants and gas processing units, our Seal Gas Heaters deliver unmatched reliability.

Technical Specification:

- Nozzle Flange Sizes: To suit customer process requirement

- Flange Rating: 150-300-900-1500-2500

- Flange MOC: CS, SS 304, SS 310, SS 316, SS 321, INCOLOY 800/825, INCONEL 600/625, Monel

- Flange Standard : ANSI/ASME/DIN

- Degree Protection of Enclosure: IP 67

- Dia of Heating Elements: 8.5mm, 12.5mm, 16mm

- Element MOC: CS, SS 304, SS 310, SS 316, SS 321, Inconel 600/625, Incoloy 800/825

- Immersion Length: To suit customer process requirement

- Control & Monitoring: Integrally Provided with

Thermocouple or PT100 RTD, Thermostat Optionally Provided with TT - Area Classification: Suitable for Flameproof/Hazardous Area

- Heat Duty: to suit customer process requirement

Key Applications:

- Oil & Gas Refineries: Maintains consistent gas temperature for compressor seal systems.

- Petrochemical Plants: Prevents condensation and freezing in seal gas supply lines.

- Power Generation: Ensures reliable sealing in turbine and boiler feed systems.

- Gas Processing & LNG Facilities: Protects against hydrate formation in critical gas streams.

- Corrosion & Pressure Resistant: Constructed in carbon steel, stainless steel or exotic alloys for harsh conditions.

- Chemical & Fertilizer Industries: Safeguards sensitive processes requiring dry, heated seal gas.

Applications

Air

Natural Gas

Nitrogen

CO₂

Instrument Air

Process Gas

Solvent

Steam Generation

Download Datasheet

Screwed Immersion Heater

Screwed Immersion Heater

Certifications

Frequently Asked Questions

Get reliable and high-efficiency Seal Gas Heaters, expertly engineered by FATI General

Equipment’s Pvt. Ltd. Designed for high-pressure applications, they deliver consistent and

effective heating of process gases with superior thermal performance and durability.